A green solution

for water purification

Mission

Every industry, needs thousands of tons of fresh water every day, all around the world, producing wastewater with different contaminants.

Then how can we protect our natural capital? Wastewater treatment, conducted by using absorbing materials, is an effective solution. Removing contaminants affords clean water, suitable for safely returning to the environment. In this context, we are proud to present CrioPurA, an innovative technology for industrial wastewater and groundwater remediation

Fundings

-

2020 - Programma Amico CNR

Funded by PoC MISE 80.000 € - TRL increase (1-->4) -

2022 - Eureka! Venture

230.000 € - Consolidation of technological maturity and technology scale-up (TRL 4 --> 7) -

2024 - Terranext

Cariplo Factory – in progress

Awards

- 2021 - Finalists EIT Jumpstarter - Manufacturing

- 2021 - Finalists StartCup CT 2021

Technology

N-methyl-D-glucamine (NMG) is a chelating species used for environmental applications thanks to its high chelating efficiency towards metal anions.

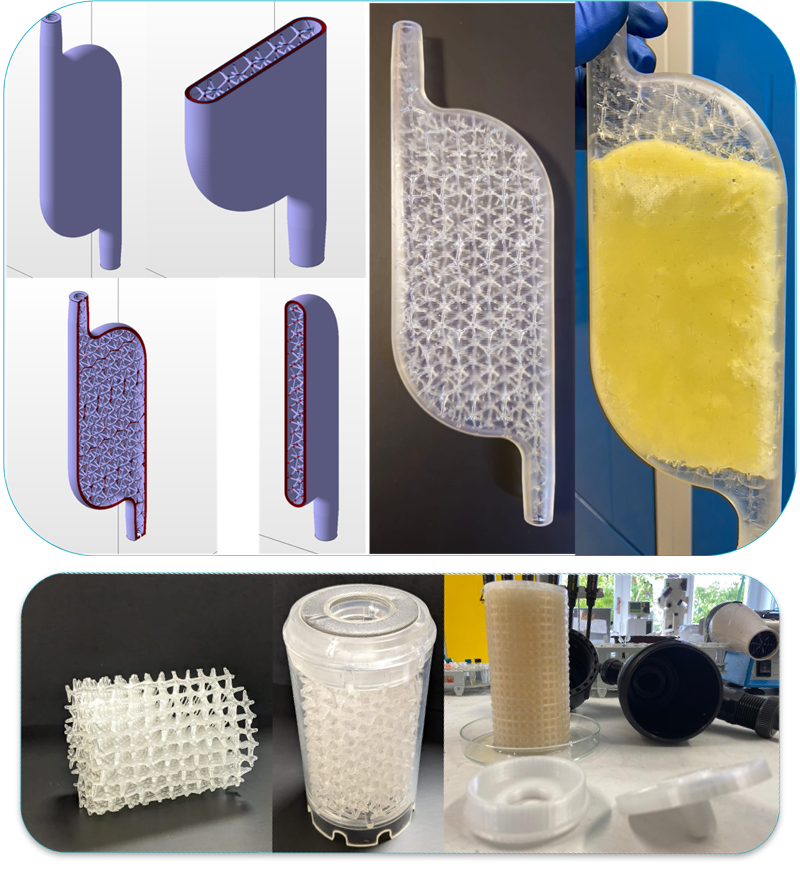

The technology presented, called CrioPurA, is a realization of NMG-based hydrogels, produced by cryo-polymerization in water. The synthesis of polymeric materials, functionalized ad hoc with chelating groups, allows low costs and eco-sustainable materials to subsequently obtain adsorbent materials. In particular, the technique adopted for the realization of the material allows to obtain structures and shapes of different sizes, with high porosity, permeability and excellent sequestering action towards boron, arsenic, chromium and other metals.

CrioPura can be regenerated, reused and used selectively for water treatment. The technology finds application as an exchange resin for the removal of inorganic pollutants from water. This allows to find a valid application and integration in the cycle of tertiary wastewater treatments, without additional costs for the implementation of the plant, as a filter for industrial plants (tanning, dyes, textiles, microelectronics), groundwater, in agriculture for boron removal.

In some areas where the presence of As (V) in water for domestic use is significantly higher than the legal limits imposed by the WHO (10 μg/L), the CrioPurA application, considering the exceptional sequestering properties, could be more effective and with lower operating costs than current technologies.

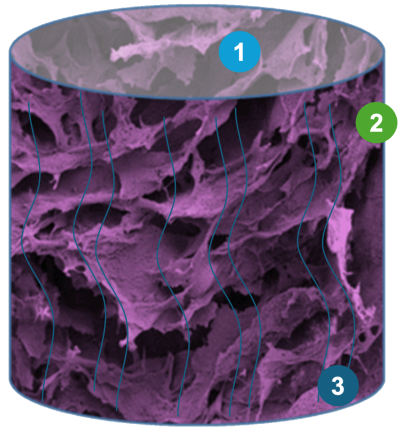

Polymeric network resulting from a cryo-polymerization process, which, after a defrosting and drying step, assumes a macroporous structure that increases the operating flux

Polymer material that makes up the sponge composed of the almost exclusive chelating material significantly increasing the sequestration capacity of the filter

A natural material - loofah - is added to the filtering system during the polymerization process as an environmentally sustainable support for increasing mechanical capacity

Patents

• Granted

• Under examination – View here

• Granted on 28/05/2024 CN114302771B

• Examination not yet started – View here

Italy Patent Application No. 102023000009954 of 05/17/2023

• Extended until 05/17/2024

Low operating costs

✓ Competitive advantage

Low energy consumption, due to lower pressure thanks to macroporous structure of the solution, and low maintenance costs, thanks to higher purification cycle capacity and reduced regeneration cycles required.

Operating pressure 0.1 bar

-

two orders lower than

the competitors

High pH range covered

✓ Competitive advantage

Higher sequestration capacity ranging from pH 2 to pH 9, making the solution reliable for different water scenarios

Wide pH range leads money and time-saving

High environmental sustainability

✓ Competitive advantage

Use of greener raw materials and chemicals for filter regeneration (over 40% of biodegradable compounds); moreover the production process occurs at 40°C using water as renewable solvent

LCA Study

How Criopura works

Criopura lab scale

Listen to the podcast about the research that led to CrioPurA created by Ilenia Di Martino

Click here to listen

Market

Market outlook

Market overview

Tertiary water and wastewater treatment market: 27,931 $ mln in 2022, with a CAGR of 4.8% between 2023 and 2030

Drivers

- Increasing global concerns regarding water scarcity

- Increasing demand for clean and industrial water

- Growing concern about the disposal of wastewater in water bodies

Restrains

- High operating costs related to the maintenance, operation, and monitoring of the treatment plant

- Operational and technical challenges for the installation and operation of equipment

Regulations

- Increasingly stringent regulations worldwide on the disposal limits of wastewater emissions*

Sources: Water and Wastewater Treatment Equipment, Market Analysis, 2023 ; Sustainable technologies for water purification from heavy metals: review and analysis, Bolisetty et al., 2019 ; Fortune business insights ; Precedence research ; Water and Wastewater Treatment Equipment, Market Analysis, Grand View Research, 2023 ; Global Water and Wastewater Treatment Equipment Market 2023-2027, Technavio, 2023 ; Global Commercial Water Treatment Equipment Market 2023-2027, Technavio, 2023.

Team

Following a continuous commitment to counter this global challenge, ranging from the sustainable design of innovative materials for water remediation to the identification of microplastics in seawater and soil, the research group decided to leave their comfort zone. The invention of criopura could have led to yet another scientific article.

Still, instead, it was patented, taken out of the laboratory, and presented to groups of investors who believed in the technology.

Founders

Andrea Scamporrino

Researcher | Institute for Polymers, Composites and Biomaterials (IPCB), CNR | PhD in Polymeric Materials for Special Uses, Università degli Studi di Catania

Sabrina Carroccio

Researcher | Institute for Polymers, Composites and Biomaterials (IPCB), CNR | PhD in Chemistry, Università degli Studi di Catania

Francesca Cunsolo

Researcher | Institute of Biomolecular Chemistry (ICB), CNR | MSc in Organic Chemistry, Università di Catania and Senior Grant, Yale University

Tommaso Mecca

Researcher | Institute of Biomolecular Chemistry (ICB), CNR | PhD in Chemistry, Università degli Studi della Basilicata

- Via Paolo Gaifami, 18 - 95126, Catania

-

Mon - Fri: 8AM to 7PM

Weekend: Closed

Cookie Policy – Privacy Policy